Scrap metal has been salvaged and reused since the early ages of metal working. From both an environmental and economical standpoint, recycling metal is extremely effective. Metals such as steel, iron, aluminum, and copper can be recycled an infinite number of times, because their metallic properties do not deteriorate with repeated melting and casting.

The metal recycling industry specializes in retrieving metal from obsolete objects so that scrap metal does not end up in landfill sites. Instead, it is converted into raw materials for new products.

Foundries rely on metal recycling for a sustainable, cost-efficient source of raw material. According to the American Foundry Society, the price of casting would increase by 20–40% without the use of recycled materials.

Refinement and purification

After separation, scrap metals undergo secondary refining. Recycling facilities sort obsolete scrap into rough categories. However, the exact chemical properties remain a mystery. In order to become a usable raw material, scrap needs to be purified to the point where it meets known specifications.

Scrap pieces with similar properties are loaded into a large furnace and heated to the appropriate melting temperature for the metal. In the refinement process, slag forms and floats to the top of the molten metal. Slag is the stony waste matter separated from metals during refining. The molten metal is then tested and further refined to meet desired quality standards. Immediately before tap out and pouring, slag and oxidized impurities are discarded to purify the metal. Once the molten metal achieves the necessary characteristics, it is transferred to a cooling vessel, ingot die, or poured directly into a mold to be solidified.

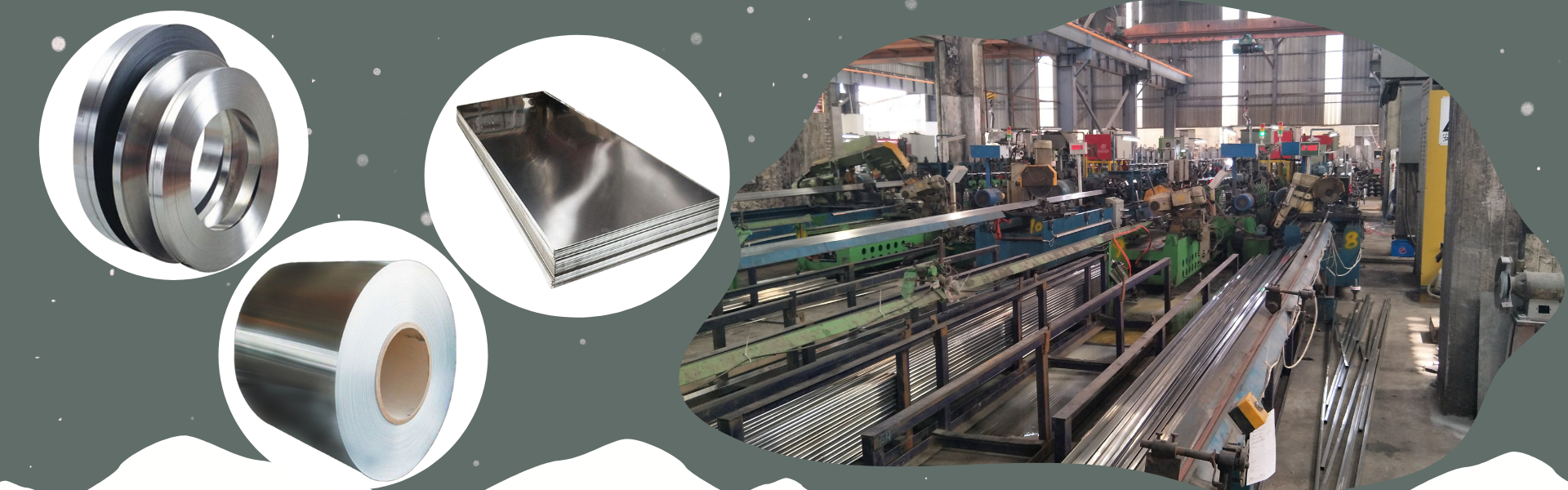

Manufacturing

Scrap metal is shipped around the globe for use in mills and foundries. Hundreds and millions of tons of scrap metal are consumed each year, making the transformation into new products to begin a new cycle.

Foundries source more of their raw materials from scrap yards and collection depots than from virgin-metal suppliers. According to the AFS, ferrous metal casters use between 30–50% internal scrap, and 40–50% scrap from external sources. This includes ferrous material from recycled cars, appliances, and scrap steel from other manufacturing operations. These figures show the incredible commitment to recycling metals within the metals industry.

Sustainability

Recycling scrap metal reduces the environmental impact of metal production. In 2016, the Bureau of International Recycling (BIR) reported that obsolete steel used as raw material in steelmaking reached 235 million tones—that is, 235 million tones of waste that did not enter landfill sites.

The metal recycling process produces fewer emissions, and requires significantly less energy than producing new metal alloys. The ISRI factsheet for iron and steel shows that recycling steel requires 56% less energy than producing steel from iron ore. In addition, by using ferrous scrap rather than virgin materials in the production of iron and steel, CO2 emissions are reduced by up to 58%.

When recycled metal is available on the market, the demand for virgin ore extraction decreases. Metal recycling transforms waste into a useful resource, conserves energy, and decreases extraction activity and resulting environmental impacts.

Post time: Dec-26-2010