The manufacture of wrought stainless steel is a multi-step process: steel scrap is melted, then cast in a workable solid shape; the solidified steel is formed, heat treated, cleaned, and polished to meet the desired specifications. Finally, the finished stainless steel is packaged and shipped to manufacturers.

Melting and casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F. Because of the extreme temperatures, precision, and large volumes required for steel production, the melting stage generally requires 8 to 12 hours. Throughout this stage, steel technicians regularly check the bath temperature and chemical composition.

After the steel alloy is completely melted, the mixture is refined. Argon gas and oxygen are pumped into the furnace, where they convert some impurities to gas and cause others to form slag for easy removal.

The refined steel is cast into machine-ready forms, including blooms (rectangles), billets (round or square), slabs, rods, and tube rounds.

Forming

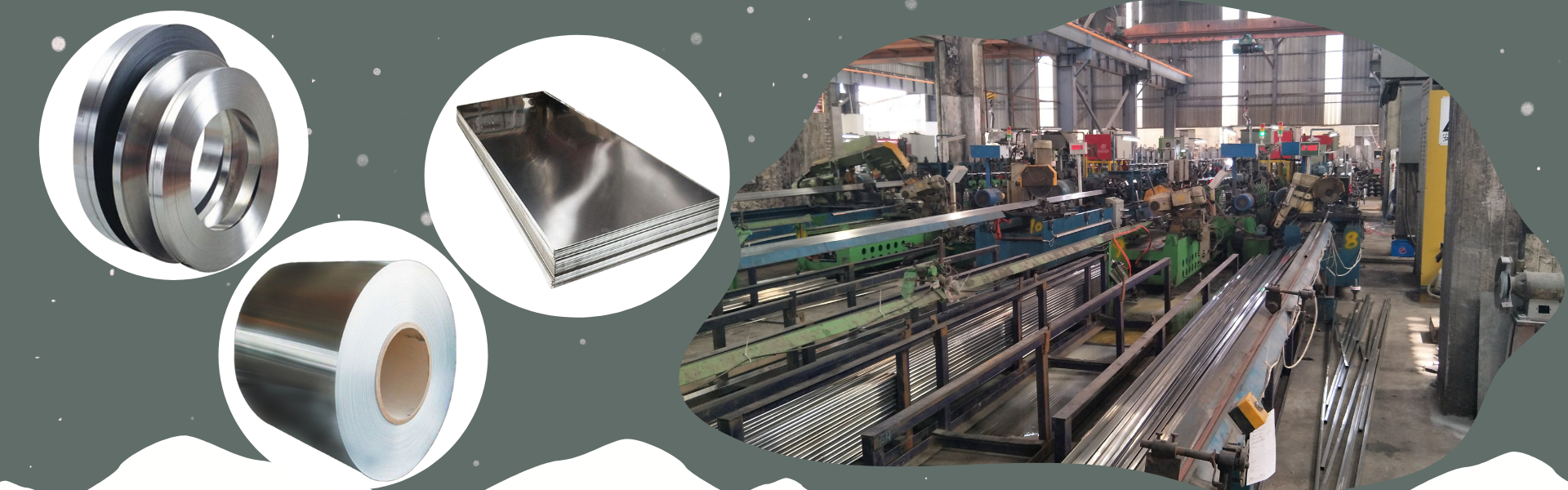

Hot rolling occurs above the recrystallization temperature of the steel. Most cast steel is formed by hot rolling: the slab, bloom, or billet is heated and passed through huge rollers, stretching out the steel into a longer, thinner form. Each slab is formed into a sheet, plate, or strip, while blooms and billets are formed into wires and bars.

Cold rolling is used when more precise dimensions or a superior surface shine are required. It occurs below the recrystallization temperature of the steel. Cold rolling uses small diameter wheels with a series of supporting wheels to create smooth, wide sheets of stainless steel to close tolerances.

Heat treatment

Heat treatment strengthens rolled stainless steel by recrystallizing the deformed microstructure. Most stainless steel is heat treated by annealing – the stainless steel is heated to an exact temperature above its crystallization temperature, and slowly cooled under controlled conditions. This process relieves internal stresses and softens the stainless steel. The annealing temperature, time, and cooling rate all impact the properties of the complete steel.

Descaling

A rolled piece of stainless steel acquires a layer of oxidized “mill scale”, which needs to be washed away to restore a shiny surface finish. Mill scale is usually removed through chemical means like electro-cleaning and pickling.

In pickling, the stainless steel is submerged in a bath of nitric-hydrofluoric acid. Electro-cleaning makes use of a cathode and phosphoric acid to pass a current onto the stainless steel surface. Both processes effectively de-scale the surface. The de-scaled metal is finished off with a high-pressure water rinse, leaving a bright, shiny finish.

Cutting

Stainless steel is cut to a specified shape and size. Most cutting is done mechanically – the stainless steel can be sheared with circular knives, sawed with high-speed blades, or blanked with punches. Alternative methods such as flame, plasma, and waterjet cutting are sometimes used.

Finishing

Stainless steels can be made with a wide variety of surface finishes. The chosen surface finish isn’t purely aesthetic – certain finishes make stainless steel more resistant to corrosion, easier to clean, or more readily used in manufacturing. The type of finish is determined by the intended application.

Surface finishes are the combined result of fabrication processes and finishing method. Hot rolling, annealing, and de-scaling produce a dull finish. Hot rolling followed by cold rolling on polishing rolls producing a bright finish, while a combination of cold rolling, annealing, and buffing with a fine surface creates a reflective surface.

An array of grinding, polishing, buffing, and sandblasting equipment is used in finishing stainless steel surfaces.

Work Hardening

Work hardening is the process of strengthening material through deformation. Stainless steels harden quickly overall, with the exact rate determined by the specific grade. Austenitic steels harden more readily that other grades.

Quality Control and Inspection

There are in-process controls throughout the manufacture and fabrication of stainless steels, but that isn’t enough to meet international quality standards. Before being shipped, each batch of stainless steel must undergo chemical and mechanical testing to ensure that it meets the desired specifications.

Mechanical testing measures the physical ability of a stainless steel to withstand loads, stresses, and impacts. Mechanical tests include the tensile, Brinell, and toughness tests described above in mechanical properties.

Chemical tests check the exact chemistry of a sample before certifying the stainless steel grade. Chemical tests are usually carried out by non-destructive spectrochemical analysis.

Corrosion resistance is of particular importance for stainless steels. Steel mills test and measure corrosion resistance with salt spray testing – the longer the steel remains unmarred by corrosion after exposure to salt spray, the higher the corrosion resistance.

Manufacturing

Stainless steels are a highly useful material used to manufacture a large range of products.

Most stainless steel is shipped to a manufacturer, where it undergoes further shaping, heat treating, machining, and welding to form a particular product. Stainless steels are frequently used to produce components for the automobile, ship, aircraft, and food service industries, among many others.

Post time: Sep-23-2021